Product Detail

Product Tags

Product Videos

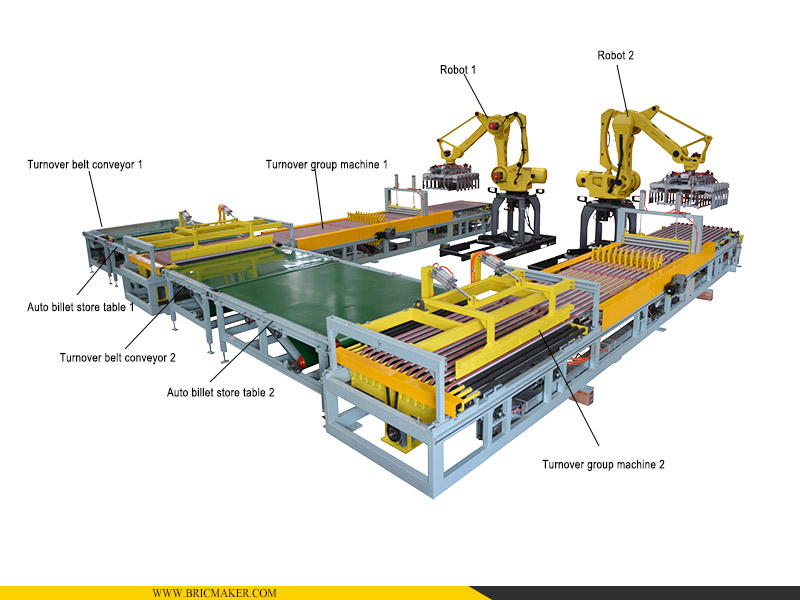

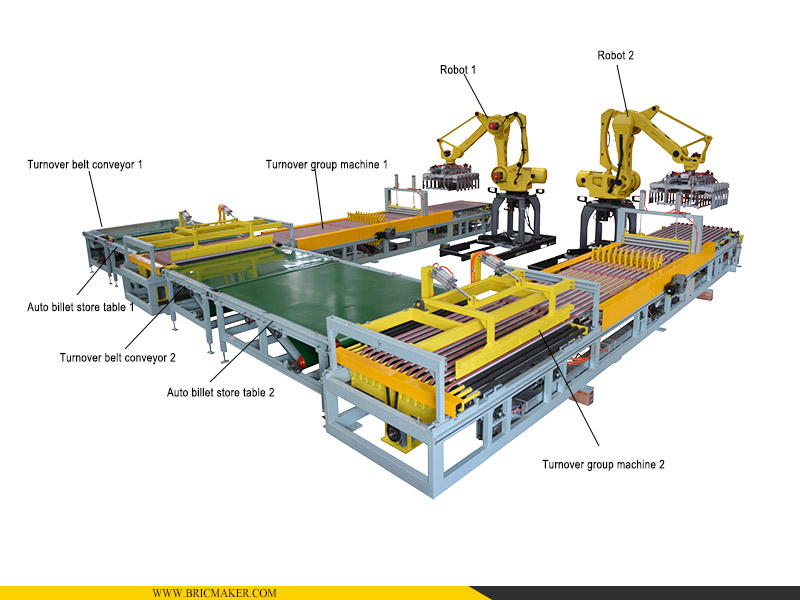

900KG Two Robots Transfer Turnover Gap Stack Brick Twin Lines

1. Brief introduction

900KG Two Robots Transfer Turnover Gap Stack Brick Twin Lines receive the green bricks from brick cutter. Then the auto line transfer, turnover, gap the bricks according to the requirements of stack type for the kilns. The twin stack lines are in parallel arranged, which greatly improve the capacity and reliability of the system. The whole process is controlled by PLC and could be remote controlled. This line is applied for modern automatic brick plant.

The stack line consists of two billet turnover and group machines, two 900KGS robots, PLC control system, conveyor belts, etc.

2. Main features:

-

Fully automatic, high output, high efficiency.

-

Reliable, flexible, easy operation.

-

The line could be single, twin or triple paralleling arranged.

-

Robot grab could be gap or no-gap.

-

The billet could be turnover 90 degree or non.

-

Applicable to different sizes of bricks.

-

Applicable to customer’s different stack type.

-

High efficiency, save manual cost.

3. Main parameters:

|

Name

|

900KG Two Robots Transfer Turnover Gap Stack Brick Twin Lines

|

|

Model

|

900kg*2

|

|

Robot number

|

2 sets

|

|

Work frequency

|

(200-300)*2

times/hour

|

|

Capacity

|

20700-36720

pcs/hour

|

|

Stack type

|

4X9,

6X18

|

|

Total power

|

(25~39+20.7) x 2

|

4. Detail image: