1. Brief introduction:

Rotary tunnel kiln, referred to as ‘rotary kiln’ for short, is an improvement and upgrade of tunnel kiln. Its biggest feature is that the brick stack does not move while the kiln body rotates. The kiln body is all made of steel structure and runs along a circular track. From front to back, it is divided into drying section, preheating section, roasting section, heat preservation section and cooling section. The billet splitting machine runs in the same direction as the kiln body, and stacks billets while splitting them. The rotating and moving kiln body moves forward intermittently on the track, the front section "eats" the bricks, and the rear end "spits out" the finished bricks and completes the whole process of drying-preheating-roasting-cooling-bricks in sequence.

2. Advantages of rotary tunnel kiln:

Low production cost, simple technological process, simple production management, green environmental protection, perfect service system, short construction period, short investment recovery period, etc.

3. Main technical parameters:

|

Parameters |

YDY75/7 |

YDY80/8 |

YDY90/9 |

YDY100/10 |

YDY100/13 |

|

Center radius diameter m |

75-100 |

80-110 |

90-110 |

90-120 |

100-180 |

|

Rail gauge m |

7 |

8 |

9.1 |

10.88 |

13 |

|

Distance of kiln column |

12 |

12 |

12 |

12 |

12 |

|

Min outer diameter m |

90 |

100 |

110 |

110 |

123 |

|

Length of center radius |

150 |

160 |

160 |

170 |

170 |

|

Layers of stack |

12-18 |

12-18 |

12-18 |

12-18 |

12-18 |

|

Daily capacity 10K PCS |

15-19 |

17-20 |

18-22 |

25-30 |

35-40 |

|

Thermal parameters monitoring |

Digital display, manual control/stand-alone inspection, manual control/automatic control are optional. |

||||

|

Desulfurization device |

Optional |

||||

|

Technical requirement |

a. Moisture content of the wet billet is not more than 16% b. the molding pressure is not less than 3.5MPa c. the raw material drying sensitivity coefficient is less than 1 d. The total internal combustion heat consumption is less than 280 kcal/kg

|

||||

|

Remarks: |

Kiln width=Rail gauge - 0.9m |

||||

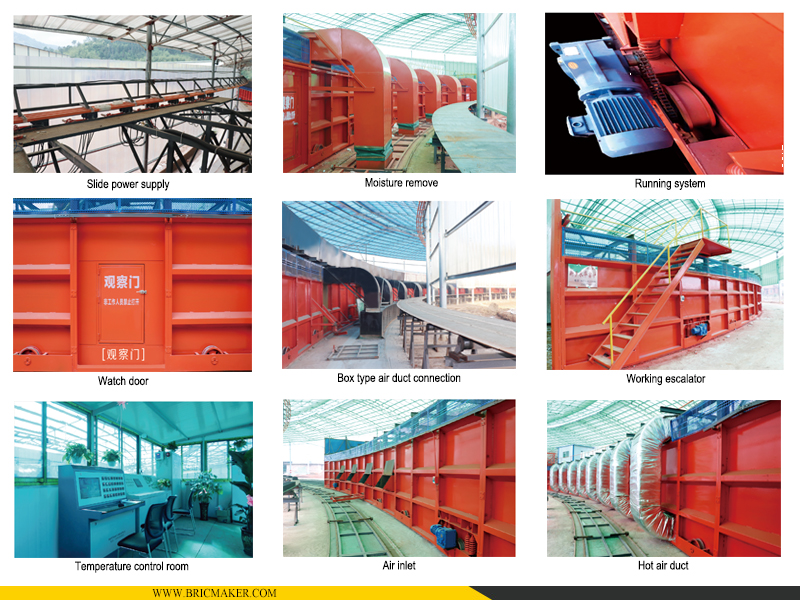

Details of rotary kiln:

4. Main construction period:

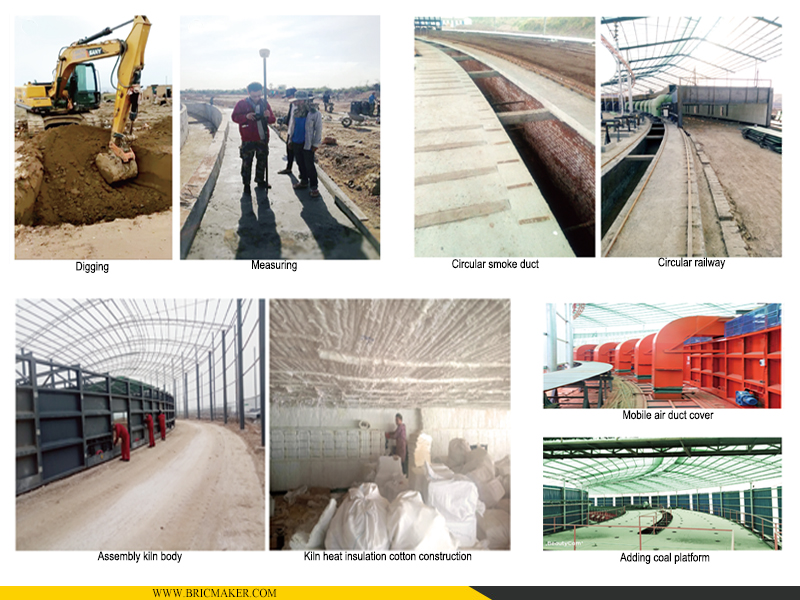

Construction pictures:

Name: General Manager

Mobile:+8613151630928

Whatsapp:+8613151630928

Email:sales@bricmaker.com

Add:No.1, Huayu Road, Donglai Development Zone, Zhangjiagang City, Jiangsu, China

We chat