3. Main parameters:

|

Robot model |

Qty(Set) |

Work frequency(times/h) |

Stack ability(Pcs/time) |

Output(pcs/hour) |

Power(kw) |

|

500kg |

1 |

240-360 |

32-48 |

14400-24400 |

5.5+22 |

|

700kg |

1 |

200-300 |

72-108 |

14400-24400 |

5.5+22 |

|

800kg |

1 |

200-300 |

72-108 |

20700-34200 |

5.5+20.7 |

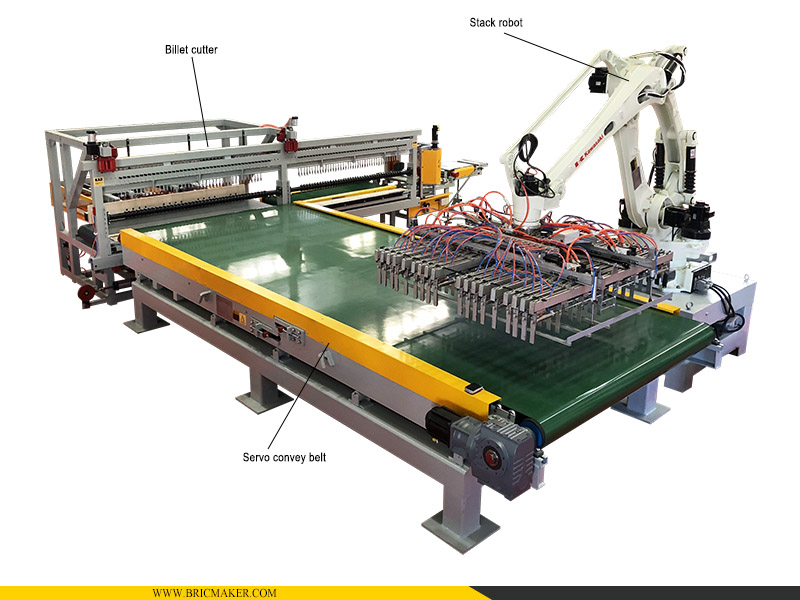

4. Detail image:

Name: General Manager

Mobile:+8613151630928

Whatsapp:+8613151630928

Email:sales@bricmaker.com

Add:No.1, Huayu Road, Donglai Development Zone, Zhangjiagang City, Jiangsu, China

We chat