Brief introduction:

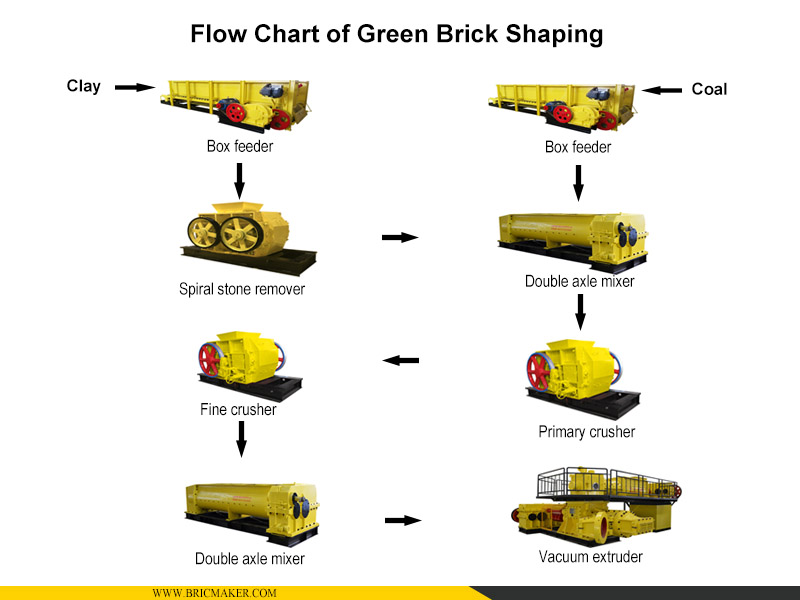

This internal combustion brick automatic line is designed to shape, cut, baking red bricks from clay and coal. The raw materials are clay and coal lumps.

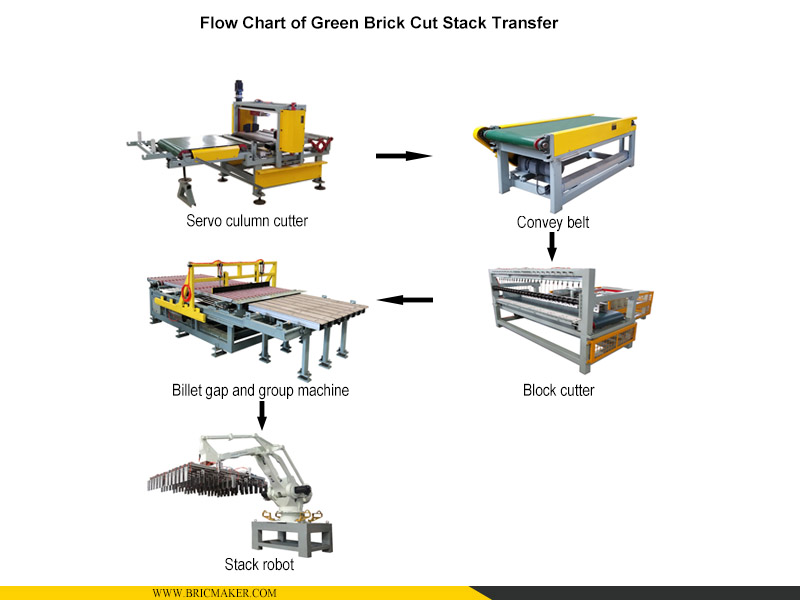

To meet the hourly capacity of 30,000 pcs, the vacuum extruder extrudes 6 bricks at the same time and the column cutter cuts 48 bricks at a time. The green brick stack robot collects 96 pcs wet bricks at a time and stack them onto the kiln car. And the green brick's shaping and stack line works 8-10 hours a day continuously.

The brick's baking technology adopts once stack and two stages baking. The kiln car is stacked with 7296 pcs wet bricks. The loaded kiln car enters the drying tunnel and firing tunnel to complete the sinter process. The tunnel kilns width is 3.6m. The daily output of the tunnel kiln is 29 cars sintered red bricks, which is 210,000 pcs red bricks.

We also offer automatic red bricks package system. The brick stacks are grabbed by a traveling crane to the brick separation platform, and the bricks are separated layer by layer through mechanical devices. Each layer of bricks is reorganized and palletized by robots. After palletizing, the brick stacks are transported to horizontal and vertical packaging machines for packaging. After packaging, the packaged brick stacks are transported to the stacking site for stacking by forklifts. When selling and loading bricks, the entire stack is then transported by forklifts to transportation vehicles.

Main technical parameters:

|

Production line name |

Internal Combustion Brick Automatic Line |

|

Raw materials |

Coal (small lump), clay (mixed with stone) |

|

Wet brick size |

84x84x194mm |

|

Extrusion line capacity |

30,000 pcs/hour |

|

Kilns |

One drying kiln, one firing kiln |

|

Kiln width |

3.6m |

|

Kiln output |

210,000 pcs/24 hours |

Detail production progress:

Name: General Manager

Mobile:+8613151630928

Whatsapp:+8613151630928

Email:sales@bricmaker.com

Add:No.1, Huayu Road, Donglai Development Zone, Zhangjiagang City, Jiangsu, China

We chat